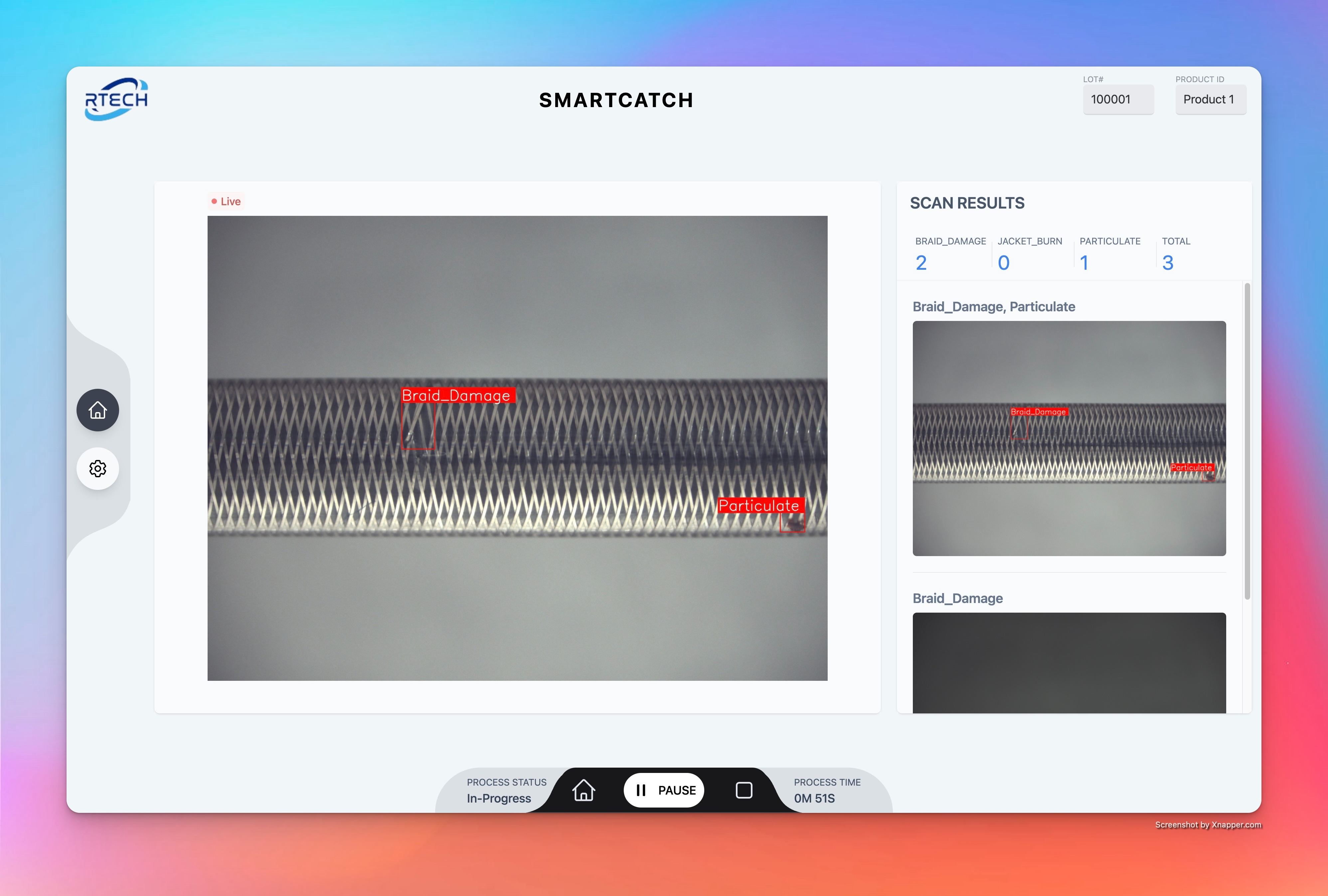

Case Study - Manufacturing Defect detection

Automatic Defect detection system for Catheter manufacturing. Features, 360 degree scanning of the Catheter to perform thorough inspection, and defect categorization.

- Client

- RTECH, Inc

- Industry

- Manufacturing, MedTech

- Services

- App development, Hardware Integration

Overview

Developed touch-screen focused cross-platform app with support for Windows, Mac, Linux and Arm based single board computer (SBC) like Raspberry-pi.

Features

- App communicates with Watlow temperature controller and Alicat Mass flow controller via Modbus protocol.

- App also communicates with Zaber's linear motion stage via ASCII command protocol.

- Support for Recipe management.

- High performance HMI (GUI) optimized for industrial touch panel.

- Configurable to support 1 - 10 Nozzle (Temperature and Flow controller).

What we did

- GUI Design

- Custom Application Development

- Hardware Integration